Apple’s new AirTag merchandise trackers are fairly small, however not fairly sufficiently small to slide into most wallets with out including an apparent little bit of bulk.

Luckily, as one proficient AirTag proprietor has discovered, that’s nothing you may’t repair with a warmth gun, a little bit of soldering and an understanding that you might completely fry your shiny new AirTag within the blink of a watch. Oh, and a 3D printer.

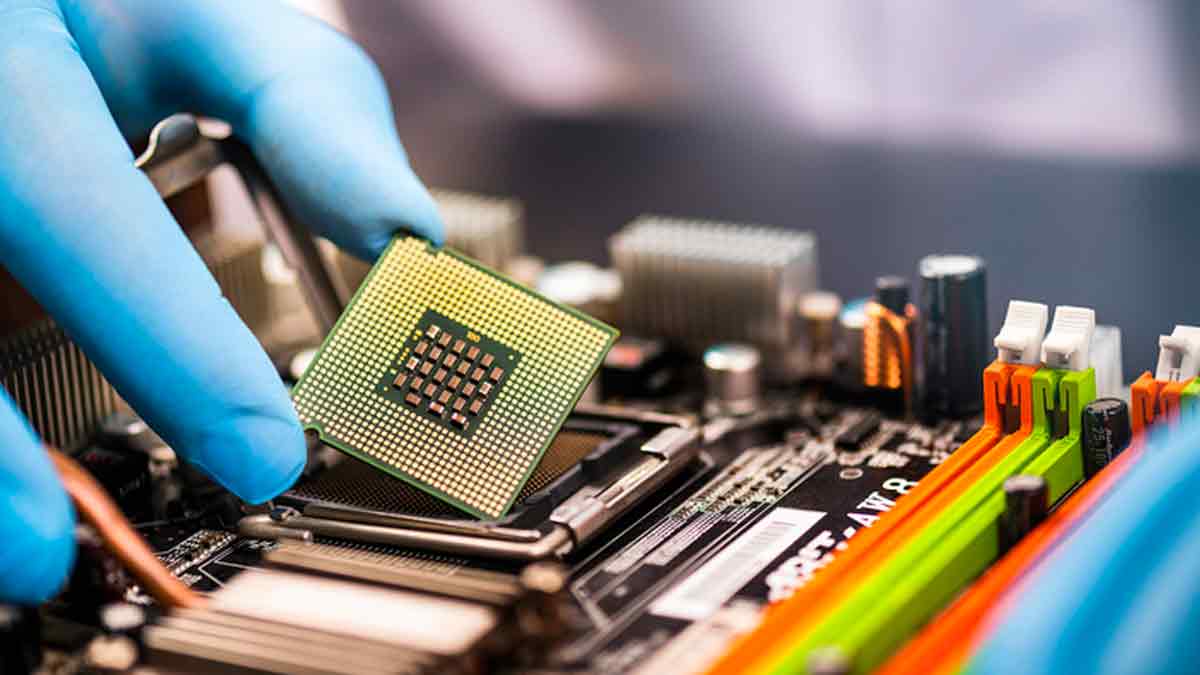

When Andrew Ngai realized that a lot of AirTag’s thickness got here from its PCB and its battery being stacked atop one another, he got down to as an alternative organize them side-by-side. With the assistance of some iFixit guides (which, by the best way, present an superior peek contained in the AirTag when you’re curious what’s in there however aren’t seeking to dissect one your self), Andrew tore the AirTag all the way down to its key elements. After ensuring every little thing nonetheless labored in its freshly disassembled state, he 3D printed a brand new case, soldered in wires to attach the board to the battery at a distance, and put every little thing again collectively. Success! And he did all of it inside simply days of AirTag being launched.

Whereas this kind of undertaking requires a reasonably broad set of expertise to tug off, Andrew has kindly dealt with one of many steps for anybody seeking to take it on: he’s uploaded the STL file for the 3D-printed card holder as a free obtain on Thingiverse. (Or you might, after all, simply purchase a Tile Slim. However that doesn’t contain soldering irons and 3D printing, so the place’s the enjoyable in that?)

[via 9to5mac]

Source link