As among the world’s largest firms make investments billions to advance battery know-how, Dominic Spooner has been working at fixing the subsequent downside: the affect of unwieldy – and environmentally unfriendly – battery casings.

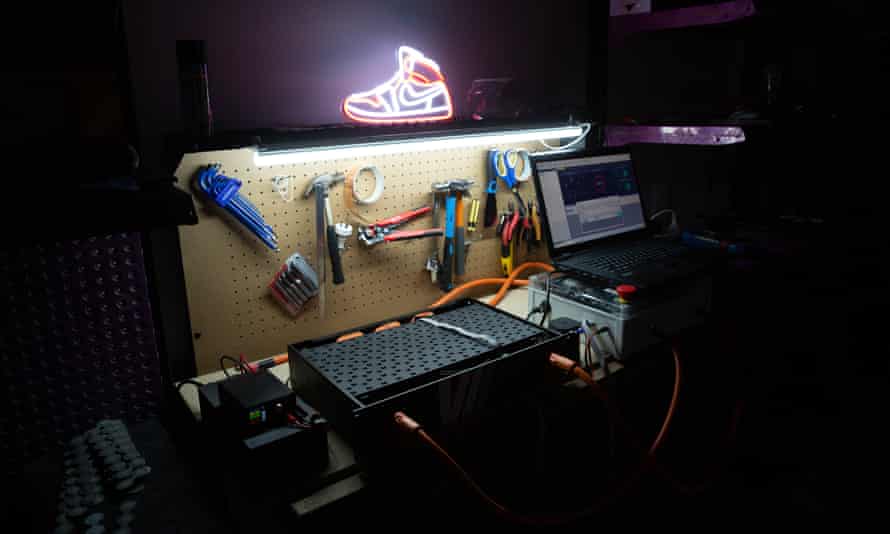

Spooner runs his light-weight battery casing know-how agency Vaulta from a shared storage in Brisbane’s north. “Batteries will change our lives in ways in which we’re possibly not even completely conscious of, however … we are able to create our personal new group of issues if we’re not cautious,” he says.

From a workspace surrounded by packing packing containers and different junk, like an previous door, Spooner and his crew have caught world consideration.

This 12 months Vaulta has signed agreements with aerospace and automotive battery firms, together with one with Braille Battery – an American producer of ultra-lightweight batteries for Nascar, IndyCar and the Australian Supercars.

Final month the corporate obtained a $297,500 federal grant to commercialise its know-how.

For these nonetheless sceptical in regards to the extent and tempo of world innovation being directed in the direction of battery know-how, the Worldwide Vitality Company says patents for vitality storage innovations have grown 4 occasions sooner than the remainder of the know-how sector, and are set to catalyse clear vitality transitions around the globe.

In 2020, Samsung spent US$710m (A$950m) on analysis and improvement of next-generation electrical automobile (EV) batteries. An Israeli agency has this 12 months begun manufacturing of an EV battery that may cost in 5 minutes.

‘We’ve obtained time now to do it proper’

So how does a tiny garage-bound Brisbane startup discover its place amongst world giants within the rush to innovate?

“It looks as if nearly each different day there are tech developments – within the cells, cell varieties, cell shapes, cell geometry – popping out of the US or Europe,” Spooner says.

“However the best way they’re being packaged, the best way they’re being housed, was simply being neglected.”

Vaulta’s know-how reduces the variety of elements utilized in battery instances. The casings scale back the battery measurement by about 18%. Additionally they don’t weld components collectively, which implies they are often taken aside and reused quite than dumped – a begin on stopping among the 98% of disused batteries that goes into landfill.

Spooner says the “lightbulb second” was a choice to work in the direction of making a casing that might be disassembled.

“On the finish of that first life, are you able to substitute cells? Can you modify them over? Is any of that possible? What we began realising was we have been simply scratching the floor.

“As a result of we’re not welding the cells, once they come out of that casing they’ve the identical properties as once they went in, and they’re higher arrange for reuse eventualities.

“[Battery innovation] is pushed by efficiency – additional, longer, cheaper … all of the issues which are going the assistance the take-up of batteries. However we’ve additionally obtained the time to do one thing proper now, to do them in a better manner. It’s not nearly recycling and reuse, however how can we get them into folks’s fingers.”

‘Flying automobiles might be in the marketplace inside a decade’

In an electrical automotive, the battery can weigh a number of hundred kilograms – a few third of the automotive’s complete weight.

Audrey Quicke, a local weather and vitality researcher on the Australia Institute, says a few quarter of the price of an electrical automobile comes from the battery beneath the hood.

“Upfront value is among the greatest limitations to EV uptake in Australia,” Quicke says. “Though the fuelling and upkeep prices are low-cost in comparison with petrol and diesel automobiles, it’s the upfront sticker value that stands out within the showroom. Any tech developments that convey down the worth of batteries would seemingly assist enhance EV gross sales.”

Quicke says a 2018 Senate inquiry beneficial a complete EV manufacturing roadmap, which might additionally cowl battery and element manufacturing, however that lots of the suggestions stay unrealised.

“EVs and batteries aren’t a excessive precedence within the authorities’s know-how roadmap, and there’s no federal electrical automobile technique to talk of,” she says.

Fast Information

How you can get the newest information from Guardian Australia

Present

“However the writing is on the wall. It’s the state governments and tech entrepreneurs which are driving the EV, charging and battery innovation in Australia. Think about what might be achieved with a nationally constant supportive EV coverage surroundings to supply path for this transition.”

Spooner says the corporate doesn’t intend to provide battery casings at a industrial scale. Reasonably the intention is to license the know-how and to work with producers in Australia and abroad. However he says the power to scale back the burden of batteries may unlock a second tranche of innovation.

Flying automobiles, for example, not sound like a movie fantasy and might be in the marketplace inside a decade.

“It may actually open the door right here or abroad for automobile makers and for [vehicles] that don’t exist but,” Spooner says.

“Regionally there’s not an enormous EV trade in Australia, however that’s to not say there gained’t be. There’s superior aerospace … manned and unmanned. Stationary storage is right here to remain as properly.

“Share good points in these types of fields are actually thrilling to be part of – for a automotive to be delivered as idea, then to be reined in and delivered to the mass client.

“The boundaries for brand new know-how to enter the market could be much less.

“However batteries even have an enormous function to play proper now. In a whole lot of methods it’s a mature know-how in its early levels of rollout.”

‘You possibly can’t beat the commute’

On the outset of the pandemic as Spooner started to work on the battery casing know-how, he noticed a neighbour, an engineer, working within the storage of a close-by dwelling.

Vaulta sublet the house quickly after and has no speedy plans to go away. For one factor, it’s too handy – proper across the nook from Spooner’s dwelling, which permits loads of time to spend along with his younger daughter.

“After we discuss in regards to the storage, it’s really an improve from the place we have been,” Spooner says.

“We have been working from dwelling. We mainly labored by means of emails, telephone calls, textual content messages.

“By way of Covid we’ve managed to discover a solution to do enterprise with Canada, components of the US. You simply form of regulate and I really fairly prefer it. You possibly can’t beat the commute and we’re fairly snug there, to be trustworthy.”

Source link